Energy-efficient transient plasma ignition and

combustion

(with Prof.

Martin Gundersen, USC Dept. of Electrical Engineering - Electrophysics)

Supported by the U. S. Air Force Office of

Scientific Research and U.S. Department of

Energy

Introduction

The electric

arc has been the ignition source of choice for most types of propulsion and automotive

combustion engines for over 100 years. It has many advantages including

simplicity, low cost, size and weight of the electronics, and it produces

sufficiently high temperatures to dissociate and partially ionize most fuel and

oxidant molecules. Nevertheless, there are also numerous disadvantages of arc

discharges, including the limited size of the discharge, the necessity for

supporting electrodes that may interfere with the flow or combustion process,

and the low "wall-plug" efficiency (i.e. ratio of energy deposited in

the gas to the electrical energy consumed in producing the discharge.) For

these reasons, many investigations of ignition of deflagrations and detonations

by alternate energy sources such as lasers have been conducted in recent years.

Still, laser ignition sources present many practical difficulties, especially

the need for reliable optical access, extremely low wall-plug efficiency, and

extremely high optical intensities needed to induced breakdown in the gas which

in turn makes it difficult to control the location and intensity of the

discharge.

The subject of

this investigation is the use of corona discharges (the portion of an electric

discharge before the onset of the low-voltage, high current arc discharge) for

the initiation of combustion in propulsion systems and internal combustion

engines. The corona discharge is basically a plasma

that is in a transient, formative phase. Corona discharges have the

potential to overcome many of these limitations of conventional electric discharges

and laser discharge for reasons that include: (1) there is better coupling into

gas because the cross-section for dissociation and ionization more nearly

matches the electron energy distribution function; (2) there are lower losses

through lower radiation, lower anode and cathode losses, and lower gasdynamic disturbance formation; (3) there are many

streamers, each of which has a similar energy content, as opposed to a single,

unnecessarily large and intense arc, which in turn can initiate combustion in a

larger volume and (4) the size and shape of the ignition volume can be tailored

using the geometry of the anode and cathode. With recent advances in pulsed

power electronics, such discharges can be produced with very high wall-plug

efficiencies in a system of reasonable cost, size and weight. Prof. Martin

Gundersen of the USC Department of Electrical Engineering - Electrophysics has developed energy-efficient corona

discharge systems that will be used for these investigations.

Recent

highlights include the first testing of corona ignition in an internal

combustion engine. Results were very

promising; indicated efficiencies were consistently 15 – 20% higher than spark

ignition under identical operating conditions and burn rates were typically

twice as fast with corona as spark ignition.

See powerpoint

presentation below for more details.

View

powerpoint presentation about corona ignition in

general (more detailed than the description below)

View powerpoint presentation

about corona discharge ignition of internal combustion engines

Recent

publications:

Wang, F., Liu,

J. B., Sinibaldi, J., Brophy,

C., Kuthi, A., Jiang, C., Ronney, P. D., Gundersen,

M. A., "Transient Plasma Ignition of Quiescent and Flowing Fuel Mixtures,

" IEEE Transactions on Plasma Science, Vol. 33, pp. 844 – 849

(2005). Download

.pdf version from IEEE website

Liu, J.

B., Wang, F., Li, G., Kuthi, A., Gutmark,

E. J., Ronney, P. D., Gundersen, M. A., "Transient plasma ignition," IEEE

Transactions on Plasma Science, Vol. 33, pp. 326-327 (2005). Download .pdf version from IEEE website

Liu, J. B., Wang, F., Lee, L., Ronney, P.

D., Gundersen, M. A., “Effect of fuel type on flame ignition by transient

plasma discharges,” AIAA Paper No. 2004-0837, 42nd AIAA Aerospace

Sciences Meeting, Reno, NV, January 5-8, 2004.

Liu, J. B., Wang, F., Lee, L., Ronney, P.

D., Gundersen, M. A., “Effect of Discharge Energy and Cavity Geometry on Flame

Ignition by Transient Plasma,” AIAA Paper No. 2004-1011, 42nd AIAA

Aerospace Sciences Meeting, Reno, NV, January 5-8, 2004.

Experimental results

Despite the

potential advantages, there have been no systematic studies of the initiation

of deflagrations or detonations using corona discharges. Preliminary

experiments on the ignition of quiescent CH4-air mixtures at 1 atm total pressure have recently been obtained in our

laboratory. To our knowledge these are the first data on flame ignition by

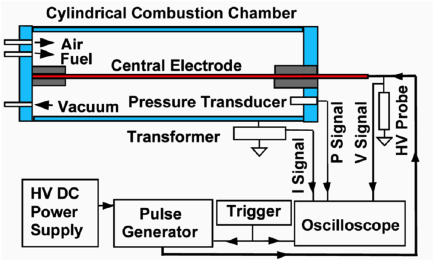

corona discharge sources. Figure 1 shows a block diagram of the

experimental apparatus for quiescent tests. It consists of the corona discharge

generator system and a test cylinder for introducing fuel, and studying

initiation of combustion. The 5.1 cm diameter test cylinder has gas inlets,

outlet and vacuum pump inlet in one end plate, high-accuracy pressure gauge for

measuring the partial pressures of the reactants, and a fast-response pressure

transducer for use during the combustion experiments.

Figure

1. Schematic diagram of corona discharge ignition system for combustion

experiments

Figure 2 shows sequential

images of a flame in a very lean mixture ignited using the corona discharge. It

can be see that the corona discharge ignites a cylindrical volume whose

diameter is more than half of the combustion chamber diameter in a very short

period of time. The ignition region surrounds the central cathode, where the

streamers are more closely spaced. The effect of the chamber diameter will

assessed to determine whether this initial flame kernel diameter is determined

mostly by the discharge or the physical size of the chamber.

|

Figure

2. Sequential photos (33 ms between images) of axial view of corona discharge

ignition of a 6.5% CH4-air mixture at 1 atm. Diameter of chamber

is 5.1 cm. |

Figure 3 shows

the energy deposited in the gas as a function of the corona power supply voltage.

For sufficiently low voltages (< 8 kV), no discharge can be initiated. Above

this voltage, the energy deposited increases rapidly with increasing voltage.

Thus, it is possible to specify a particular amount energy deposition depending

on the application. An order of magnitude range of energy deposition is shown

in Fig. 3. Figure 4 shows the ignition delay time (time lapse between the

discharge and the pressure reaching 10% of the peak pressure in a

constant-volume chamber) as a function of the discharge energy. It can be seen

that there is an "optimal" energy of about 200 mJ for this case,

below which the delay time increases rapidly, and above which the delay is

nearly constant. Thus, there is little motivation to increase the energy above

this optimal value. This behavior was seen for all mixtures tested in our

preliminary experiments. As expected, the optimal energy was found to be higher

for leaner mixtures.

Figure 3. Energy deposition vs supply voltage

for corona discharge sources

Figure 4. Combustion rise time as a function of

pulse energy for CH4-air mixtures at 1 atm showing presence of

"optimal" energy (~ 200 mJ in this case).

Figure 5 shows

the ignition delay time and Figure 6 shows the combustion rise time (time lapse

between the pressure reaching 10% and 90% of the peak pressure), both as a

function of equivalence ratio. For all corona ignition cases shown, the

"optimal" energy was used. Also shown are corresponding results for

an arc discharge (~ 70 mJ) at different locations within the chamber. These

figures show the most significant finding of the preliminary experiments - the

corona discharge leads to much more rapid combustion (by about a factor of 3)

than an arc discharge for all mixtures tested, even for the most advantageous

arc discharge location.

|

|

|

|

Figure 5. Ignition

delay time as a function of equivalence ratio for CH4-air mixtures

at 1 atm for arc and corona ignition sources having "optimal"

energy (see text).

|

Figure 6. Combustion

rise time as a function of equivalence ratio for CH4-air mixtures

at 1 atm for arc and corona ignition sources having "optimal"

energy (see text).

|

There are many

factors that may contribute to the advantageous results of the corona

discharge. Clearly the geometrical advantage of the corona is present (many

optimal streamers vs. one unnecessarily large and intense arc.) Still, it is

expected that the performance of the corona ignition system would be superior

to an arc discharge system having several independent discharges because the

corona streamers are distributed throughout the annular region between the

coaxial electrodes whereas the arcs would be restricted to the regions between

their respective electrode pairs. Moreover, these multiple electrode pairs

would certainly yield greater heat and radical losses and would be a less

energetically efficient means of ignition.

This more rapid

combustion with corona discharges can be exploited in a number of ways. In the

case of pulse detonation engines, it could lead to smaller, lighter engines

with higher specific impulse. For premixed lean-burn gas turbines, it could

provide the needed acceleration and stabilization of combustion to make such

devices practical in a wider range of applications. Moreover, even for mixtures

that are not especially lean, the corona discharge decreases the time required

for combustion to occur in a given volume, which means that the residence time

of reactants in the high-temperature region of the combustor can be decreased,

which in turn leads to lower thermal NOx formation.

Not proficient

in English? Try the Swedish version.